ink-up the block and stamp the screen

"dAb" - gian pangaro

click

here for a 3-minute movie

"dAb" recreates the interaction between stamp, inkpad,

and paper by allowing the user to create a 'digital stamp' on

the computer screen. Using digital RFID's (radio frequency ID's)

for each stamp, "dAb" detects the acts of inking the stamp and

stamping the screen.

Background: Normal stamps and inkpads pad share a

complementary relationship, since each depends upon the other in order to

perform the act of stamping an image. The stamp permanently possesses an image

that it can stamp upon paper, but must get its ink (and color) from the inkpad.

The inkpad, on the other hand, has colored ink, but needs the stamp's rubber

pattern in order to transfer its ink to the paper. Usually, the inkpad is

limited to one color, and the stamp's image can be transferred to paper using

the ink of many different inkpads. The inkpad, however, is not limited to

one image, but can rely upon many different patterned stamps to transfer its

color to paper.

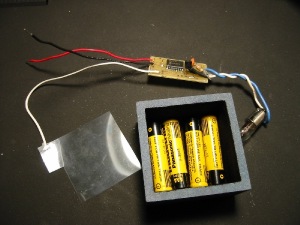

Materials: Wood, acrylic, colored vellum,

electronics, magnets, batteries, clear conductive plastic.

Interaction: Users use "dAb" as they would an ordinary

stamp and inkpad, except that the stamp must be "inked" once for each stamp

transferred to the screen. When the user inks the stamp, the inkpad lights

up, transferring its color to the acrylic block (the stamp) as light. When

the user stamps the screen the inkpad's color appears as a 1.5" square on

the screen. The colored squares created by the stamp arrange themselves on

the screen in a tiled pattern. The user can tile 5 x 5 mosaic-style patterns

using the three available colors in any order. Once the screen is filled,

the pattern is erased with the next stamp and a new pattern begins. The java

program in Proce55ing also contains a timer to erase the screen no one has

interacted with the system within the past 30 seconds.

Technology: "dAb's" major technology consists of modulated

radio frequency signals passed between two capacitively coupled conductors

(the top of the inkpad and the bottom of the stamp). Once received by the

stamp, signals are demodulated in analog circuitry and turned into regular

9600-baud serial signals. These are read by a microcontroller, checked for

errors, and then passed on to the computer's serial port for use in Proce55ing.

Inside each inkpad is a small circuit board containing a PIC16f84, a reed

switch to sense stamping, a transistor, and an incandescent light bulb (which

provides a nicer light than an LED but consumes about 3 times as much power),

and batteries. A clear conductive material called PEDOT, acts as the capacitive

antenna. The acrylic cube (the stamp) was left as plain as possible to preserve

its ability to transmit light to its outer surfaces. A layer of PEDOT on the

bottom of the cube acts as the receiving antenna for the inkpad's RFID. A

magnet on each of its bottom corners triggers reed switches in the inkpads

during stamping. The inkpad bases save battery life when they are not in use,

and only light up and transmit their ID's when stamped with the cube. Finally,

another sheet of PEDOT is laid over the computer screen in order to detect

the RF transfer of the stamp's ID to the computer.